·带式连续输送,生产效率高

·气动加压,自动调整偏带,走带平稳,运行可靠

·加热区独特的弧面设计,使不了紧贴加热面,受热均匀,粘合效果好

·粘合的工艺参数(温度、时间、压力)可根据粘合料的需要设定

·上下加热区的温度可根据需要分开设定

·电脑控制,主要控制元件为进口器件

·采用无缝、防静电输送带

·采用出料台风冷却结构

·Conveyer belt yields high productivity

·Pneumatic pressurization,self-correcting of deviation of the belt make steady and reliable conveyance possible.

·The unique surface of the heating area makes the cloth pressed closer to the surface,achieving good effect in fushing and keeping well-proportioned temperature.

·Technological parameters in fusing can be adjusted according to the different material to be fused.

·The temperature of the up per and undersurface of the heated area can be set separately if necessary

·Computer controlled machine,of which main control components are imported.

·No junction and anti-static fusing seamless belt.

·According to actual demand,choose wind cooling system.

前送带

前送带 调偏气缸

调偏气缸 电磁阀

电磁阀 温控器

温控器 粘合带

粘合带 微动开关

微动开关

YTT系列熨烫工作台

YTT-BDZ3 II 电热蒸汽组合熨烫台

DYTT-BQ琴式熨烫工作台

DYYT-BS系列吹吸风熨烫工作台

YTT-PF熨烫工作台

GZY系列工业用全蒸汽熨斗

HS系列工业用全蒸汽熨斗

GZY系列工业用电热蒸汽熨斗

XXT560吸线头机

DYZ型验针机

MYSJ系列面料预缩机

YB系列验布机

热熔粘合机系列NHG-F500

热熔粘合机系列NHG-600、NHG-900

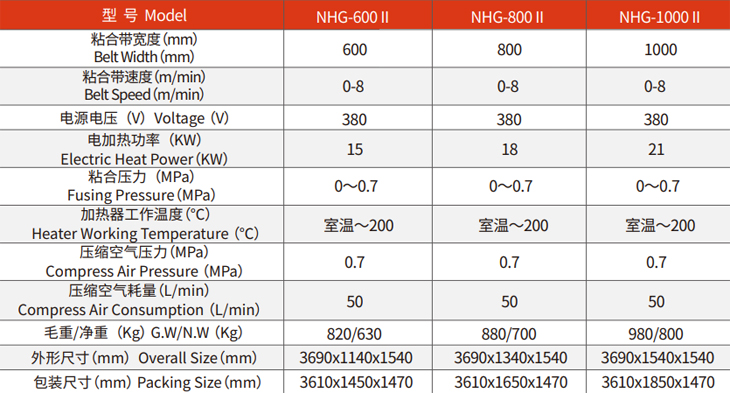

热熔粘合机系列NHG600-II、NHG800-II、NHG-1000II

热熔粘合机系列NHG-1600II